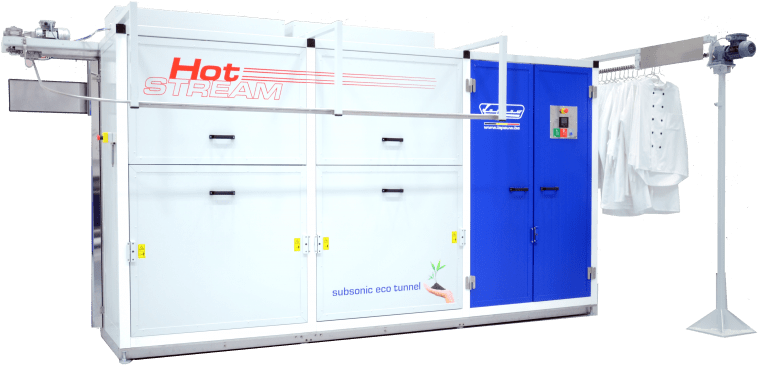

HOTSTREAM TUNNELFINISHER (STEAM)

Thanks to the trademark process, where the garments pass shoulder to shoulder through the narrow drying chamber, the HotSTREAM achieves a quality finish that is similar to manual finishing. This makes the HotSTREAM the ideal machine to increase productivity on your high end apparel like :

- Retirement homes

- Chef’s wear

- Workwear that comes in contact with customers

- ….

The Range

| Type | items/hr | Type | items/hr |

| MONOT1 | 120 | DUOT2 | 750 |

| MONOT2 | 250 | DUOT3 | 850 |

| MONOT3 | 400 | DUOT4 | 1000 |

| MONOT4 | 550 | DUOT5 | 1300 |

| MONOT5 | 750 | DUOT6 | 1600 |

* Production capacity is measured with poly/cotton and can vary in function of like type of linen, thread count and weight.

WHY THE LAPAUW TUNNEL FINISHER

SHOULDER TO SHOULDER: A FIRST CLASS FINISH

Garments pass through shoulder through the narrow drying zone.

- Full body of garment is exposed to the air flow, enhancing drying.

- The high air stream shakes the items and beats them against the stainless steel side panels, assuring enhanced mechanical action and removal of wrinkles

ALSO 100% COTTON

Thanks to the narrow passage, the HotSTREAM also handles effortlessly heavy items and 100% cotton.

STAND-ALONE OR INTEGRATED SYSTEM : YOUR CHOICE

The HotSTREAM is an open system, prepared to be installed in any type of garment conveyor system.

However, the machine can be configured also as stand-alone system.

Production capacity goes from <100 items/hour to 1600 items/hour.